Runtime Efficiency and Mass Activation in Reflect-O-Ray Low-Intensity Infrared Systems

In a large shop, true efficiency begins when the walls, doors, and structure are held in temperature equilibrium — preventing freeze-ups, helping wash bays dry quickly, and reducing burner runtime.

In the previous article, Underfloor Heating — The Uncomfortable Truth, the physics were laid out clearly.Hydronic slabs can feel pleasant underfoot, but in a large-volume shop they are:

- slow

- inefficient

- reactive instead of proactive

- and always chasing the environment rather than stabilizing it.

Those weren’t opinions — they were the result of thermodynamics.

Underfloor heat has one foundational limitation: it warms only the slab. One surface, one plane, one source. And because the slab is a low-temperature radiant surface, it cannot project infrared into walls, doors, equipment, or structural mass. It cannot activate the surfaces that determine whether a shop gains or loses heat. So it defaults to warming air and hoping convection will carry comfort — a mechanism that cannot stabilize a large building.

The real question, then, is which system heats the building — not just the slab.

1. The Core Scientific Requirement:

Heaters Must Warm the Mass, Not Just the Floor

A shop is not a small enclosed space.

It contains:

- tall ceilings

- heavy equipment

- steel walls

- overhead doors

- pits

- tool benches

- wash bays

- constant air turnover

- structural surfaces that strip heat rapidly if left cold

To stabilize that building, the heat must occupy the mass of the structure:

- walls

- ceiling panels

- tools

- crane rails

- columns

- concrete

- vehicles

When those surfaces are warm, the building returns heat gently, invisibly, and consistently back into the space.

That is equilibrium.

Any system that fails to warm those surfaces directly will always:

- fight condensation

- fight stratification

- run long cycles

- and never achieve comfort near the workers.

Underfloor heating, by design, warms only the slab — a single plane that cannot influence the building’s mass.

Radiant heat, when properly engineered, activates the entire mass.

And importantly, the slab becomes part of that mass. When radiant systems warm structural surfaces — walls, steel, overhead panels, equipment, and doors — the concrete floor is naturally included as well, becoming one of the largest and most stable thermal reservoirs in the building. Its value is not in being the sole heat source, but in being activated as one component of a fully warmed envelope.

That’s the pivot point.

And it leads to the solution.

2. Infrared Radiant Heating:

The Physics-Aligned Mechanism

True low-intensity infrared doesn’t rely on heated air.

It delivers energy as waves — interacting first with the electron clouds of solid matter.

- surfaces absorb IR

- electrons elevate in energy state

- that energy disperses through the atomic lattice

- vibration increases

- solids become warm mass

- warm mass re-radiates back into the space

Walls, ceiling, equipment, doors, and floors all participate.

This is the thermodynamic opposite of underfloor heat:

Instead of trying to push warmth through the air to reach cold mass, radiant systems warm the mass directly and let physics stabilize the space.

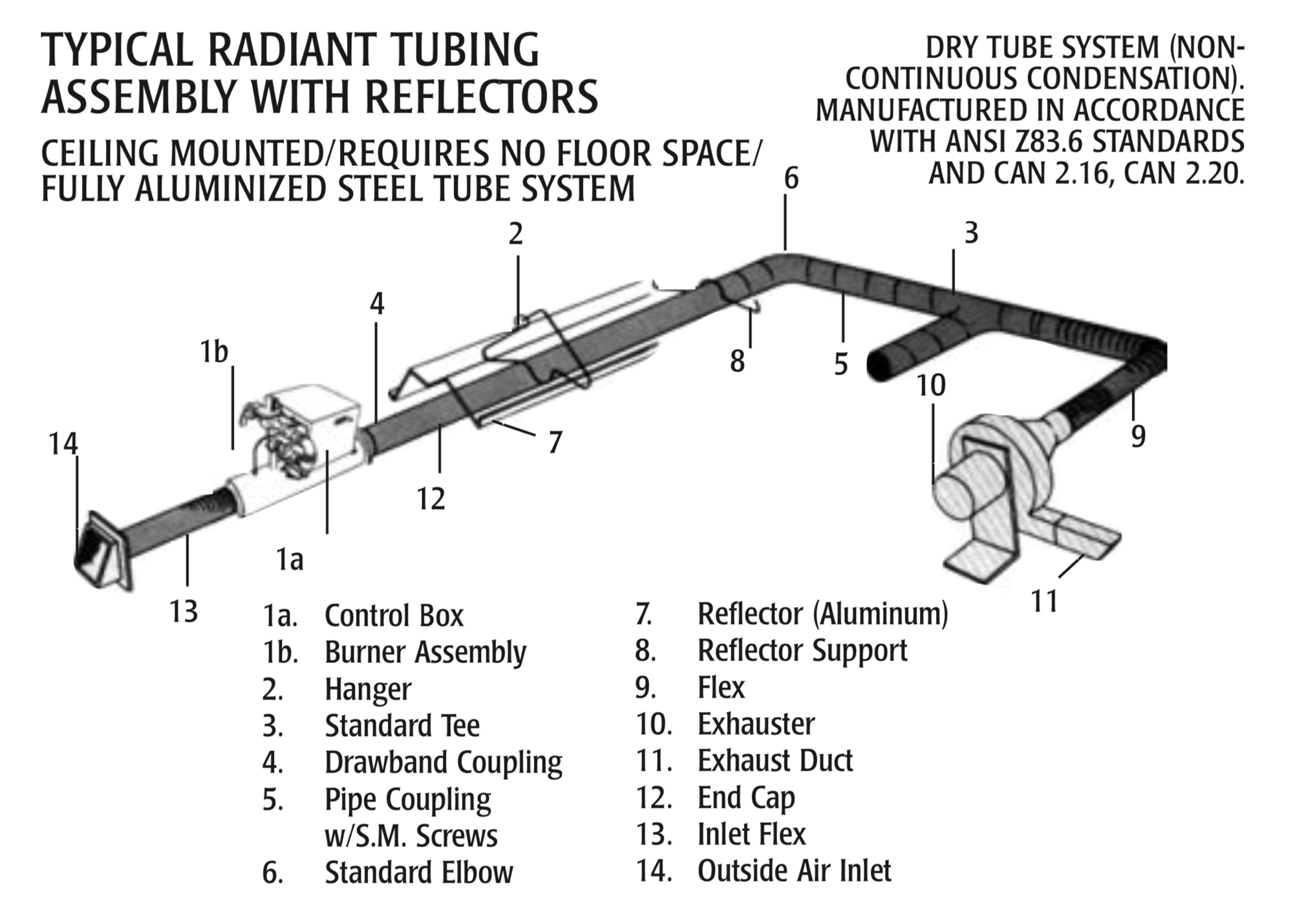

3. The Reflect-O-Ray Architecture

And Why No Other Radiant System Delivers Mass-Level Heating the Same Way

Reflect-O-Ray is not a “radiant unit.” It is a modular radiant architecture.

Its strength is not a single component — but the ability to shape radiant density to the building through engineered choices in:

- tube diameter

- burner count

- system patterning

- exhaust placement

- venting sequence

- balanced emissivity tubing

- and, when required by ceiling height, combustion control tubes to soften front-end temperature profiles

These are not decorative technicalities. They are tools that govern how deeply radiant energy penetrates mass and how evenly it is distributed.

Tube Selection: Scalable by Building Size

- 3.5-inch systems for compact workshops and barns

- 4-inch systems for large agricultural and commercial shops

- 6-inch systems for hangars and industrial spaces

Wider tube diameters allow longer radiant travel before exhaust — stretching radiant length proportionally with building volume.

Under radiant systems that lack diameter variation or the material composition to preserve radiant energy, long runs collapse into weak convection far before they reach their end.

Reflect-O-Ray extends useful radiant output.

Because it scales to the building.

4. Balanced Emissivity Tubing:

The True Radiant Engine

Reflect-O-Ray’s low-mass, 22-gauge aluminized steel spiral tubing is already optimized for controlled emissivity — allowing energy to be both carried and released intentionally along the run. In many commercial shops, this tubing alone provides ideal radiant performance.

In lower-ceiling trade spaces or worker-dense areas, or sensitive animal environments, combustion control tubes can be introduced at system start to moderate the front-end intensity curve.

The point is simple:

Reflect-O-Ray doesn’t force one tube type into every project. It matches emissivity, diameter, and pattern to the space — so radiant energy is metered where it’s needed and preserved where reach matters.

That is engineered balance.

5. Vacuum Venting:

The Mechanism That Makes Multi-Burner, Long-Reach Radiant Work

Most radiant systems are linear: one burner, one run, one exhaust — with strong heat at the front and weak performance downstream.

Reflect-O-Ray uses vacuum venting:

- burners positioned strategically

- flame drawn through the system

- radiant output renewed as it travels

- intensity balanced along the entire length

- exhaust shared at the terminus

This allows:

- multi-burner architectures

- extended runs

- long-span shop coverage

- radiant density mapping over cold structural zones

- patterned layouts instead of simple straight sticks

Vacuum venting prevents the classic problem in straight radiant systems:

- hot front — cold rear — convection at the end.

Instead, radiant output remains effective until the final, intentional cool-down at the shared exhaust.

The building receives balanced radiant energy — not a blast followed by a fade.

6. Minimal Temperature Spread:

Not 30°F Hot Spots and Cold Corners

Reflect-O-Ray systems are engineered to minimize surface temperature differences across the shop:

- floor

- walls

- working plane

- equipment

- overhead doors

And that’s what eliminates condensation.

Not claimed numbers. Not precision charts. Just the observable reality of thermal equilibrium when mass is uniformly warm.

Users consistently report:

- even comfort

- stable working zones

- no hot-front / cold-back patterns

- and dry walls even in wash bay use

A radiant system shouldn’t create one overheated district to brute-force warmth into another.

It should cause the building to settle into balance.

That’s what Reflect-O-Ray does.

7. The Reality Check:

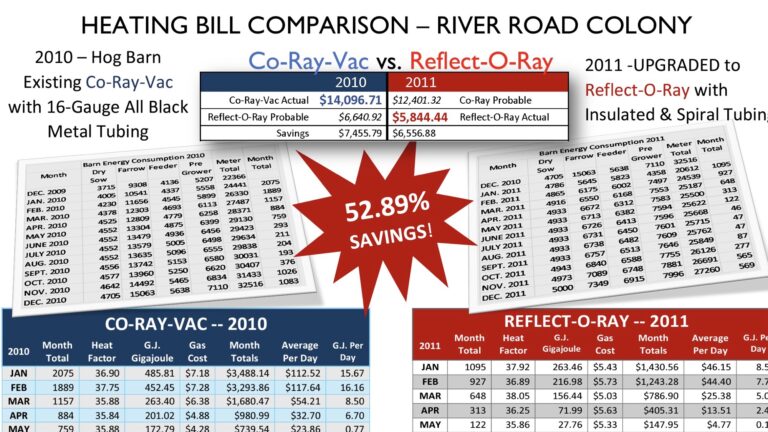

Combustion vs Energy Efficiency

Here is the line that changes everything:

True efficiency is run-time.

When a building’s mass is warm, Reflect-O-Ray cycles less often because walls, ceiling, and equipment return heat back into the space.

Underfloor systems can burn perfectly clean every minute of the day and still operate inefficiently if they must chase heat through the entire slab and into the air.

Combustion efficiency:

- measures how cleanly gas burns

- 98% ≈ 100% for practical purposes

- and tells you nothing about building performance

Energy efficiency:

- shows how little the system must run

- how fully the building stores radiant energy

- and how stable temperatures remain through load swings

Reflect-O-Ray systems often idle because the mass itself keeps comfort intact.

Hydronic boilers run — and run — because heat must be rebuilt from the floor upward every time the building loses temperature.

You cannot win the runtime battle from the floor. Physics won’t allow it.

8. Fast Response, Fast Recovery, and No Trapped Summer Heat

Because Reflect-O-Ray does not thermally isolate a slab from the earth, it does not create the “summer heat trap” that hydronic insulation produces.

When outdoor weather warms:

- mass naturally cools

- the building vents heat organically

- no chilled loops or cooling pumps are needed

- and the shop becomes comfortable without trying to fight its own slab

In winter:

- radiant systems answer load instantly — not hours later

Doors open? Heat returns quickly, from mass already energized.

Weather swings? Response is immediate.

Wash bays running? Walls and overhead panels stay warm, so moisture doesn’t collapse onto cold mass.

That is the structural advantage of radiant.

And it is something underfloor can never replicate.

9. Zoning Flexibility and Worker Comfort

Because Reflect-O-Ray is not locked to a single heated slab:

- heat can be softened where workers stand long hours

- intensified at exterior doors

- feathered near office partitions

- focused over mechanical bays

- dialed back near welding areas

The system can be patterned, scaled, and tuned.

No single temperature dictates comfort for the entire building.

Underfloor systems don’t have that option.

Their heat is monolithic — whatever the slab is, the entire shop must be.

Reflect-O-Ray can sculpt comfort to the work being done.

10. Dry Walls, Dry Doors, Dry Workspaces

When the entire mass of a building shares a similar temperature profile:

- condensation never finds a cold surface to deposit on

- dirt lines and streaks don’t form

- steel doesn’t sweat in winter transition

- wash bays recover quickly after use

Humidity doesn’t punish radiant systems, because radiant systems prevent cold surfaces from spawning it.

Underfloor is always fighting a temperature gap.

Reflect-O-Ray closes it.

11. Final Comparison

Underfloor heating warms one surface and hopes heat migrates. It works comfortably in small rooms. In large-volume shops, it becomes a battle against physics: reaction is slow, runtime is long, condensation forms, mass activation is weak, summer heat traps in the slab, and zoning is nearly impossible.

Reflect-O-Ray, by contrast, heats the building itself — radiant activation of mass, scalable tube diameters, balanced emissivity, vacuum-vented multi-burner layouts, optional combustion-control tubes, zonal density mapping, minimal temperature spread, rapid response, and short burner cycles that maintain stable, comfortable surfaces.

The building repays that design by storing and returning heat naturally, shortening burner cycles and stabilizing temperature with far less runtime.

That is equilibrium.

And that’s why runtime — not combustion rating — is the real metric of efficiency in a shop.

Reflect-O-Ray simply aligns with that truth.

Truck Washes, Humidity, and the Power of Mass Activation

Warm air always carries moisture. When that air meets a cooler surface, it cools through its dew point and releases that moisture as fog, mist, or droplets. In a truck wash — constant spray, saturated air, rapid thermal swings — that exchange is unavoidable if structural surfaces remain cooler.

A heated slab doesn’t fix the mechanism. It warms the floor, the air lifts that heat, and the moisture in that air condenses wherever it lands on cooler mass. Heavy spray and cold exterior panels keep the cycle going.

Relying only on slab heat and air exchange becomes a losing battle:

- fog lingers

- visibility drops

- and vehicles must sit for hours to dry — simply because the building still contains cooler mass.

Reflect-O-Ray interrupts that physics by warming the structure itself — steel, overhead panels, doors, walls, rails, columns, and the slab. When surfaces are warm, air doesn’t cool on contact and moisture has nowhere to settle.

Once the mass is warm:

- dew-point margins widen

- fog clears faster

- condensation stops

- wash bays recover quickly

Dry trucks. Dry walls. Clear air. Rapid recovery — in high-moisture environments, mass activation is the only reliable path to equilibrium.