Understanding Air-First vs Surface-First Heating

Air temperature isn’t barn temperature. A barn is floors, walls, cages, and the ceiling. When all of those sit close in temperature, the room stays dry and easy to run. Air-first (convection) heat warms the air and the slab, but the rest lags. Surface-first (radiant) heat warms the building itself so everything comes up together.

Think of it this way: are you heating the air or the building? Heat the air with convection and you’ll chase it with fans and multiple sources to push warmth around. Heat the building with radiant and the mass holds the warmth, moisture has nowhere cool to land, and the air follows—less stratification, less run time.

1) The air-first problem (what goes wrong)

Air is easy to warm, but it does a poor job warming mass. Air-first systems put heat into the air or the slab and then wait for walls and steel to catch up. While they lag, you get:

- Stratification: the warmest air pools high, the coolest air settles where birds live.

- Condensation spots: cooler surfaces fall near the dew point, moisture clings, and drying slows.

- Over-driven sources: slabs get pushed hotter to hold target air, and fans must work to mix warmth.

- Chasing the weather: when outside conditions swing, recovery takes time because the building itself is still cool.

Result: the barn can feel warm, yet surfaces are uneven, so it never truly settles.

2) The surface-first solution: mass activation

Reflect-O-Ray low-intensity infrared doesn’t heat the air first. It’s absorbed by the big surfaces—floors, walls, cages, and ceiling—warming the outer skin, conducting inward, and gently re-radiating so nearby materials pick it up. Because many surfaces “see” the heater at once, they rise together and the temperature spread tightens quickly.

When the mass is warm, the air warms second-hand off those surfaces and stays steady with far less stratification. When we keep the major surfaces within about 0.5–1.0 °F (0.3–0.6 °C) and above the dew point, moisture has nowhere cool to land. No need for an over-hot slab or a fan scramble just to carry warmth around.

Short version: Heat the mass. The air follows.

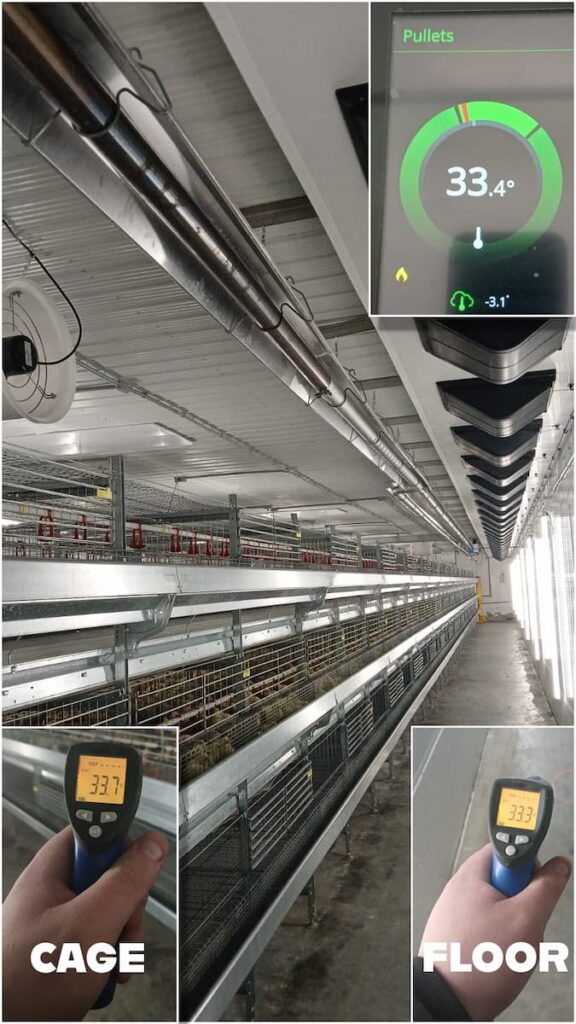

3) Field Check Reflect-O-Ray Pullet Barn

Outside: −3.1 °C (26.4 °F) 2025-11-26

| Location | °C | °F |

|---|---|---|

| Barn setpoint / air | 33.4 | 92.1 |

| Floor | 33.3 | 92.0 |

| Lower wall (~30–50 cm) | 33.7 | 92.7 |

| Cage / steel | 33.7 | 92.7 |

| Far ceiling panel | 33.7 | 92.7 |

Reading taken during a strong north wind (wind-chill ≈ −15 °C).

What it shows:

Ceiling, walls, steel, and floor clustered at 33.3–33.7 °C (92.0–92.7 °F)—a spread of about 0.4 °C (~0.7 °F).

That’s everything heating!!

4) “Won’t radiant make my cages too hot?”

Not with the right radiant. Reflect-O-Ray is gentle by design. It pairs lower-BTU burners with front-end Combustion Control Tubes (CCTs), low-mass 22-gauge spiral tubing, and vacuum venting to spread a soft, even infrared pattern. Floors, walls, cages, and ceiling warm together. In practice, cage temperatures track within ~0.5–1.0 °F (0.3–0.6 °C) of nearby surfaces—consistent with the Spring Point check—so birds and equipment sit on the same temperature, not spikes.

It’s also efficient. Because the building mass holds heat, Reflect-O-Ray simply tops up—like refilling a coffee cup—instead of running constantly. Hot-water/fin + fan systems often need near-continuous operation to keep air on target and can react more slowly to quick weather swings. With radiant, the building is the buffer, so temperature recovers quickly without overheating the slab or cranking fans.

5) Setpoint reality — why underfloor runs hot

When the floor is the heat source, you have to run it hot to lift the room. Warm air peels off the slab and rises, giving up heat to cooler walls, cages, and the ceiling. Without constant push from the slab, bird-level air sags—so the floor runs hotter while vertical mass lags.

Example A — Underfloor (air-first) snapshot

| Location | °F | °C |

|---|---|---|

| Floor (slab) | 100.9 | 38.3 |

| Cage / steel | 88.9 | 31.6 |

What the snapshot shows:

The slab at ~100.9 °F (38.3 °C) with cage steel at ~88.9 °F (31.6 °C) is a classic air-first spread: the source is hot, but vertical mass trails. Big surface gaps invite condensation—if walls/steel sit below the air’s dew point, moisture lands on those cool spots.

Surface-first radiant flips this. Energy lands on surfaces directly, so the floor doesn’t need to be over-driven. Walls, cages, ceiling, and floor rise together and settle within about 0.5–1.0 °F (0.3–0.6 °C)—no “too-hot floor,” no fan scramble.

Big surface gaps are air-first physics; tight surface spread is surface-first physics.

6) Combination air-first systems (slab + ceiling fins)

Modern builds often pair hydronic slabs with ceiling hot-water fins as part of the ventilation/heating package. The rationale is practical: heat at the floor, temper at the ceiling, then use fans to blend.

But it’s still air-first. The slab warms air near the floor, fins warm air at the ceiling, and fans move air between—while walls, cages, and other mass lag. When those surfaces sit below the air’s dew point, moisture lands on the coolest steel and wall panels. To hold bird-level temperature you push the slab hotter and run fans more, which can risk draft at chick height and creates a ventilation penalty: you exhaust warm, moist air you just paid to heat.

Bottom line: more hardware to buy and run (boiler, pumps, fins, fans), more runtime to chase air, and installed cost that’s typically ~2–3× a Reflect-O-Ray surface-first radiant system—yet you still haven’t heated the mass.

7) Surface-first (Reflect-O-Ray): heat the barn, not just the air

Reflect-O-Ray sends energy to the building itself—floors, walls, cages, ceiling—so they warm together. Temperatures sit in a tight spread (~0.5–1.0 °F / 0.3–0.6 °C typical) and stay above dew point, so there’s nowhere cool for moisture to land. The room runs dry and steady.

- One system, two jobs. Hold comfort at low burner duty and gentle airflow day-to-day; when needed, run longer to lift mass temperature for fast dry-out after washdowns.

- Lower fan & pump hours. You’re not “carrying heat” with air, so ventilation can stay low and steady; less warm air is exhausted outside.

- Quick response. The mass is the buffer: burners just top up (like refilling a coffee cup) when weather swings, without overheating the slab or cranking fans.

- Simple kit. One heat source to buy and maintain—no boiler + fins + mixers—yet you’ve actually heated the mass, which is what controls moisture and stability.

Bottom line: Surface-first radiant sets the building temperature; air-first systems chase it

This document reflects independent research and analysis of infrared radiant heating principles by Enviro-Smart Inc. It is intended for educational purposes and does not represent official technical literature, engineering position, or product claims of Combustion Research Corporation. All conclusions, interpretations, and recommendations expressed herein are solely those of the author.

More on radiant & underfloor heating

UNDERFLOOR HEATING

The Uncomfortable Truth About Hydronic Slab Systems Many shops install hydronic underfloor heating because it seems like a straightforward application of basic…

Read article →THE SCIENCE OF INFRARED HEATING IN POULTRY BARNS

Why Heating Mass — Not Just Air — Changes Everything A deep scientific overview of radiant physics, mass activation, and the engineering…

Read article →