Infrared radiant tube heating is a low-intensity radiant heating method used in large-volume buildings such as shops, barns, warehouses, and industrial facilities.

Instead of using air as the primary heat carrier, these systems transfer energy by radiation directly to floors, equipment, structure, and occupants.

This document provides a neutral, engineering-oriented overview of how infrared radiant tube systems work, the major components, and the underlying heat-transfer mechanisms.

For a general overview of radiation, convection, and conduction as the three fundamental modes of heat transfer in buildings, see:

Solaronics – Radiation vs Convection Heating Principles.

For a formal mathematical treatment of thermal radiation exchange between surfaces, see the classic NASA reference:

NASA – Thermal Radiation Heat Transfer (Siegel & Howell).

1. What “Infrared” Means in Heating Applications

Infrared (IR) is electromagnetic radiation with wavelengths longer than visible light and shorter than microwaves.

In building heating, the relevant band is thermal infrared, which is associated with heat transfer by radiation between surfaces.

- Infrared energy travels in straight lines at the speed of light.

- It interacts primarily with solid and liquid surfaces, not with air.

- Absorbed radiation increases the temperature of the receiving surface.

A familiar example is solar gain on a cold day: air temperature may be low, yet surfaces exposed to sunlight (ground, vehicles, building facades) warm significantly.

Infrared radiant heating systems apply the same principle inside a building using a controlled combustion source and engineered emitters.

2. What Is Infrared Radiant Tube Heating?

Infrared radiant tube heating is a form of low-intensity radiant heating in which a gas burner heats a long metal tube.

The tube surface reaches an elevated temperature and emits infrared radiation.

Reflectors mounted above the tube direct a significant portion of that radiation downward toward the occupied zone.

Unlike high-intensity spot heaters, which concentrate energy in small areas,

tube systems distribute the heat source over length.

This allows coverage of large floor areas with relatively uniform radiant flux.

3. Primary System Components

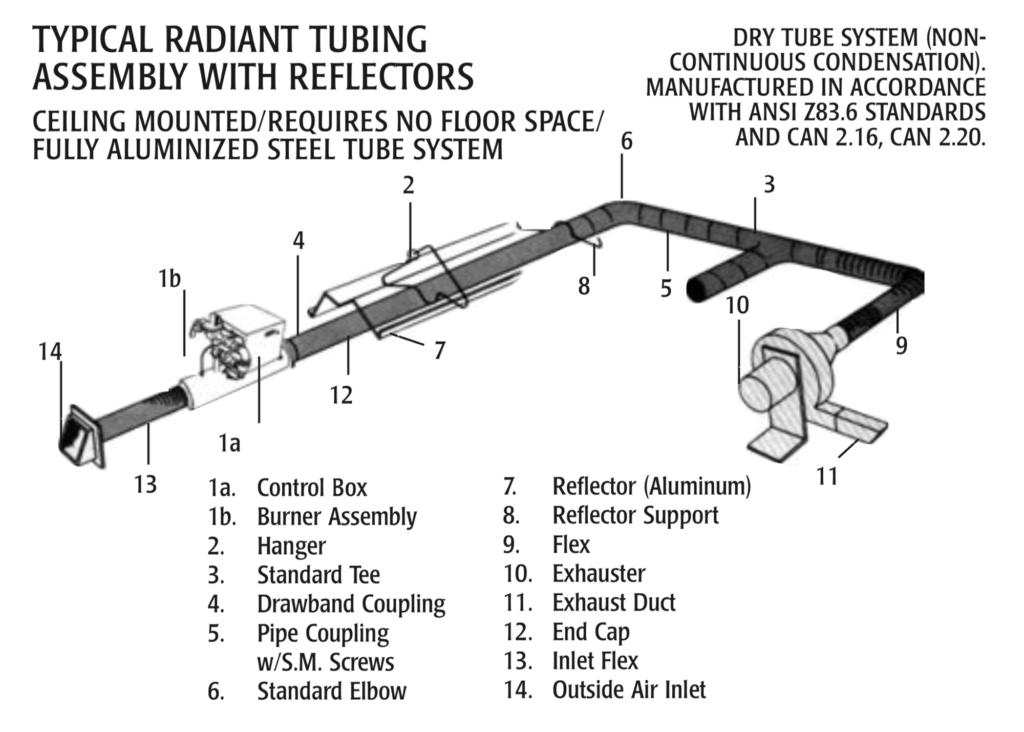

3.1 Burner Assembly

The burner is the combustion source.

It mixes fuel gas with combustion air, ignites the mixture, and transfers hot combustion products into the tube.

- Pressure systems push combustion gases through the tube.

- Vacuum systems draw combustion gases through the tube using an exhaust fan.

The burner supplies controlled heat input to the tube.

The tube surface is the primary radiant emitter.

3.2 Radiant Tube

The radiant tube carries combustion heat away from the burner.

As products of combustion move through the tube, convective heat transfer raises the tube wall temperature.

The hot tube surface then emits infrared radiation into the occupied space.

3.3 Reflector

The reflector redirects radiant energy downward toward the floor and working plane,

increasing useful energy delivery and reducing heat loss to the roof structure.

3.4 Venting and Exhaust

Combustion products are discharged outside the building through an engineered venting system that maintains proper airflow and safety conditions.

3.5 Controls and Thermostats

Radiant systems use space and zone temperature controls that regulate burner operation.

Because radiant systems heat mass rather than air directly, control strategies differ from conventional forced-air equipment.

4. Heat Transfer Mechanism in Radiant Tube Systems

- The burner combusts fuel and transfers hot products into the tube.

- The tube surface temperature increases along its length.

- The hot tube emits infrared radiation.

- Radiation is absorbed by floors, equipment, structure, and occupants.

- These surfaces then transfer heat to surrounding air by convection and secondary radiation.

Air temperature increases as a secondary result of surface heating.

This inversion of the traditional “heat the air first” sequence defines radiant heating behavior in large spaces.

A detailed comparative study of infrared radiant heating versus floor heating in large-space buildings can be found in:

Comparison of the Floor and Infrared Radiant Heating System in Large-Space Buildings (Jia et al., 2019)

.

5. Radiant Tube Heating vs. Warm-Air Heating

Warm-air systems heat air directly and distribute it through fans or unit heaters.

Heated air stratifies and is easily lost through doors, infiltration, and ventilation.

Radiant tube systems deliver energy directly to solid surfaces.

Floors and structure store heat and re-radiate it over time, making these systems far less sensitive to air movement and short-term air loss.

6. Typical Application Domains

- Agricultural and livestock buildings

- Poultry production facilities

- Vehicle service bays and truck garages

- Fabrication and machining shops

- Warehouses and distribution centers

- Aircraft hangars and high-bay industrial spaces

7. Common Misconceptions

“Radiant systems only heat the air.”

Radiant systems heat surfaces first.

Air temperature rises as a consequence of surface heating.

“Radiant only works directly under the tube.”

Low-intensity tube systems spread radiant flux along their full length using reflector geometry and layout design.

“All heat disappears when a door opens.”

Heat stored in slabs and structure remains after brief air exchanges and continues to reheat the air once doors close.

8. Temperature Stability and Mass Effects

- Warm-air systems store heat primarily in the air.

- Radiant systems store heat primarily in building mass.

Because mass has slow thermal response, radiant-heated buildings experience smaller temperature swings and improved stability during ventilation or door operation.

Broader analysis of radiant system performance in relation to building thermal mass can be found in:

Performance of Radiant Heating Systems of Low-Energy Buildings (Sarbu et al., 2017)

.

9. Summary

- Radiant tube systems use infrared radiation rather than convected air.

- Energy is delivered directly to floors, structure, equipment, and occupants.

- Reflectors and venting control energy direction and combustion safety.

- Thermal mass becomes the primary heat reservoir.

- These systems perform well in large, high-bay, and high-ventilation buildings.

Understanding these fundamentals provides a sound framework for evaluating radiant heating system performance, layout behavior, and real-world operating characteristics.