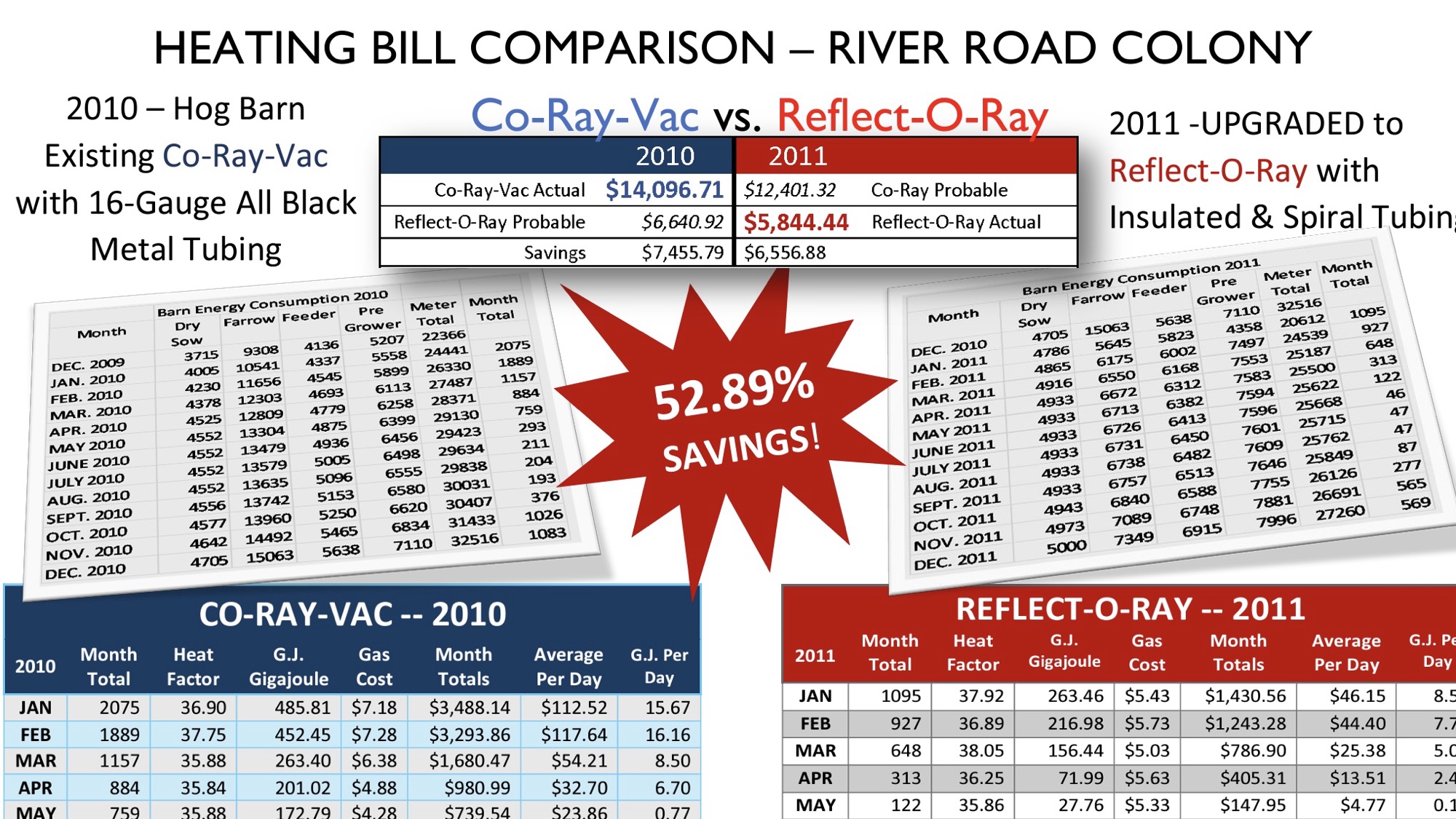

At River Road Colony, a significant transformation in heating technology led to substantial savings and set a new standard in energy efficiency. This change was marked by the shift from the Co-Ray-Vac system to the advanced Reflect-O-Ray system in their hog barns—a decision that has not only reduced costs but also enhanced environmental performance.

Background on the Transition

Old System vs. New System

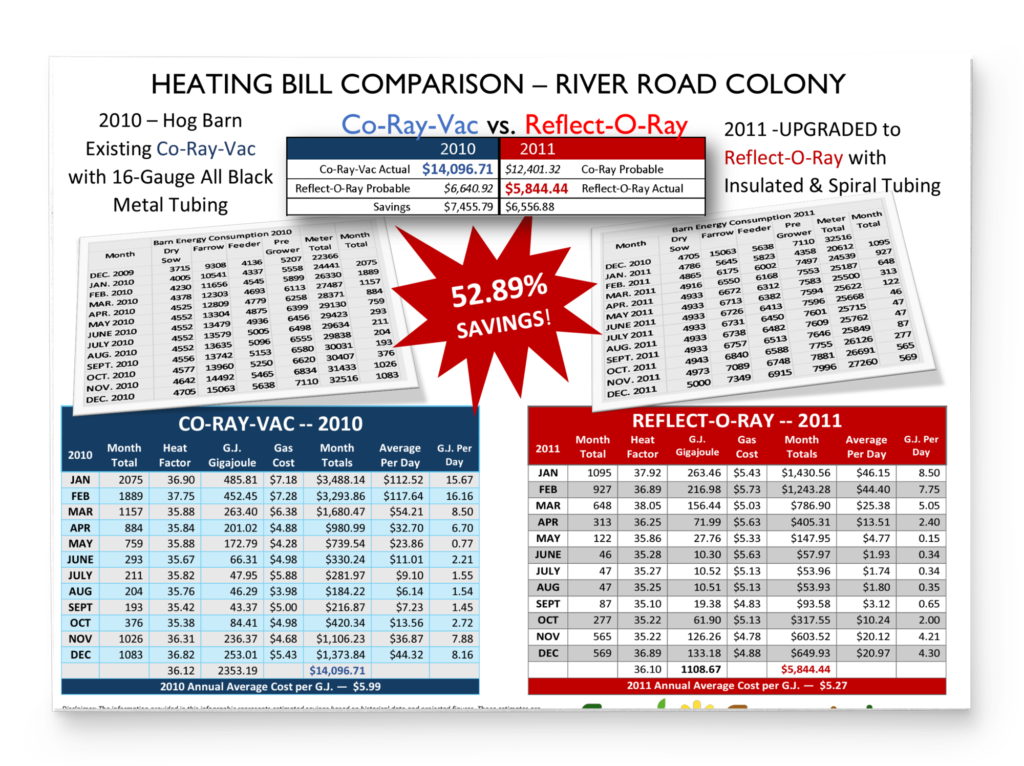

Up until the end of 2010, River Road Colony utilized the Co-Ray-Vac system in their hog barns. Although this system was capable of adequately heating the barns, it was burdened with inefficiencies due to its reliance on traditional heavy 16-gauge black metal tubing throughout its entire structure. In pursuit of a more efficient alternative, the colony turned to the Reflect-O-Ray system. Renowned for its patented 22-gauge aluminized steel alloy spiral tubing, Reflect-O-Ray not only offered quicker start-up times but also ensured more uniform temperature distribution within the barns. This advancement significantly enhanced heat transfer and reduced energy consumption, marking a substantial improvement in heating efficiency.

Launching the Fuel Efficiency Study

After observing the performance of the Reflect-O-Ray system for a year, the colony’s electrician initiated a comprehensive fuel efficiency cost savings study. The goal was to quantitatively assess the financial and environmental benefits of the new heating system compared to the old Co-Ray-Vac system. This study aimed to provide a clear and quantifiable comparison based on actual consumption data and operational costs.

Assessing the Crucial Role of Heat Factor

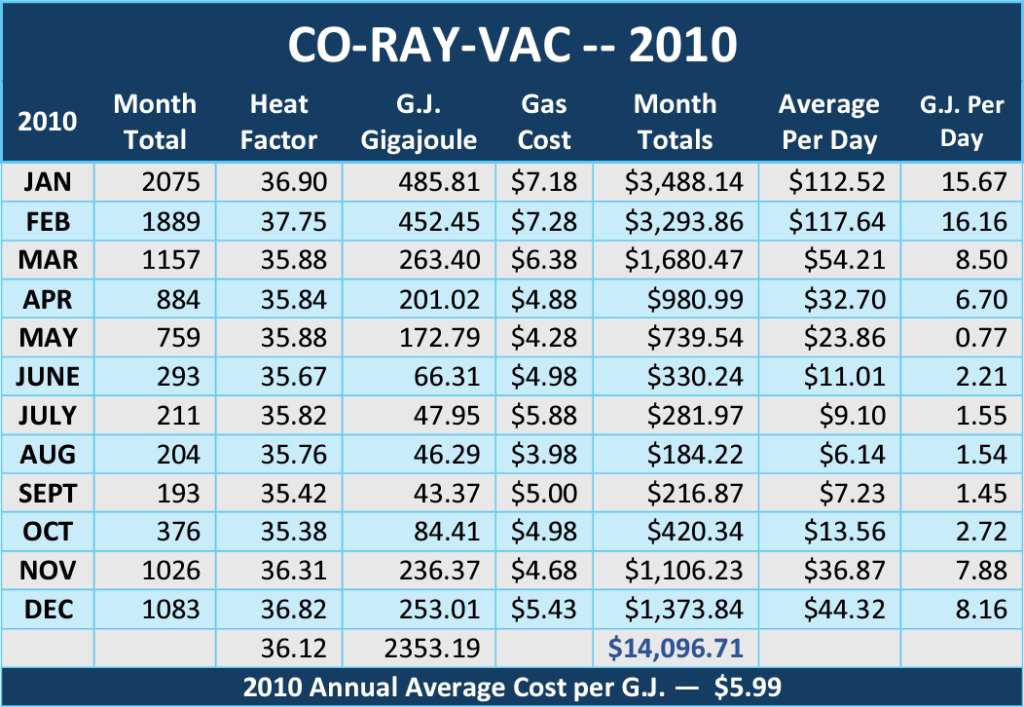

The significance of incorporating the heat factor into this analysis cannot be overstated. With average heat factors of 36.12 in 2010 and 36.10 in 2011, the external temperature conditions remained virtually identical across both years. This consistency is pivotal in validating that the substantial savings observed were directly attributable to the enhanced efficiency of the Reflect-O-Ray system, rather than any variations in external environmental factors.

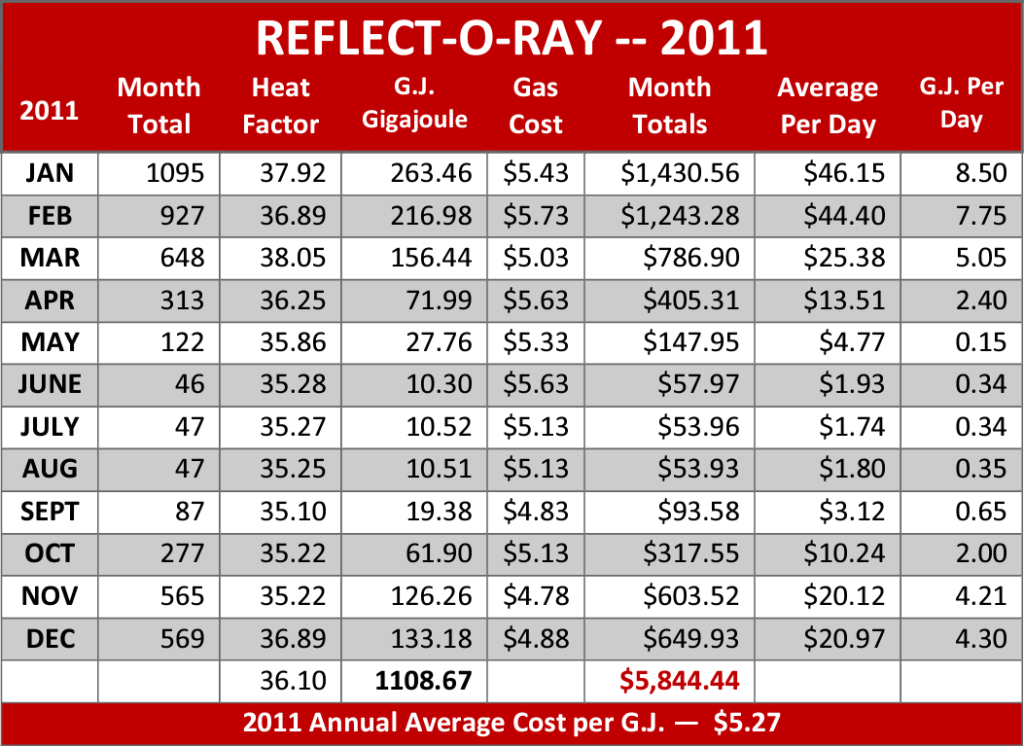

Visual Data: Charts on Fuel Consumption and Cost Savings

In this blog post, accompanying charts visually depict the fuel consumption and costs for 2010 and 2011, highlighting the dramatic reductions achieved:

2010 (Co-Ray-Vac System):

Year Total: 2,353.19 G.J., costing $14,096.71

2011 (Reflect-O-Ray System):

1,108.67 G.J., costing $5,844.44

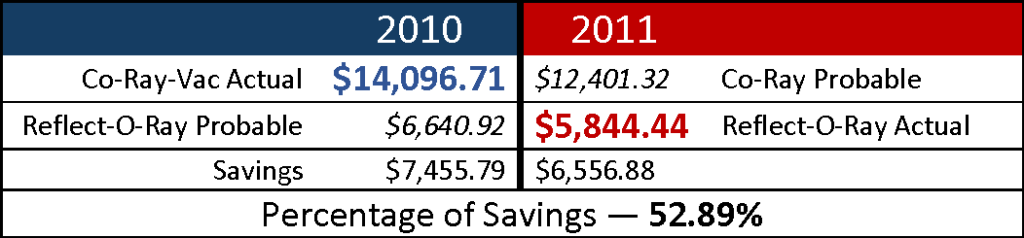

Probable Cost Analysis

The “Probable Cost” is an estimated figure, calculated to demonstrate what the heating costs might have been in 2010 had the Reflect-O-Ray system been installed using the actual consumption data from 2011. This analysis allows us to fairly compare the old and new systems under the same price conditions:

Probable Cost for 2010 with Reflect-O-Ray:

$6,640.93, with savings of $7,455.78 or 52.89%.

This cost was derived by applying the 2010 gas price of $5.99 per gigajoule to the 2011 actual consumption amount of 1,108.67 gigajoules. The calculation illustrates the cost efficiency of the Reflect-O-Ray system, showing potential savings if it had been used a year earlier, providing a direct comparison to the actual expenses incurred with the Co-Ray-Vac system in 2010.

In Conversation with Jake

In 2015, we caught up with Jake, the now retired manager of River Road Colony, who had overseen the colony for nearly 40 years. In a brief yet insightful interview, Jake shared his experiences and the impactful benefits of the Reflect-O-Ray system in their shops and barns.

Technical Merits of Reflect-O-Ray

The system’s superior design ensures faster and more even heat distribution, crucial for the hog barns at River Road Colony. This capability not only enhances comfort but also contributes to better production without increased energy expenditure.

Jake’s Endorsement and Its Impact

Jake’s endorsement of the Reflect-O-Ray system, based on decades of leadership and experience, underscores its effectiveness. Under his guidance, the colony became a model of energy efficiency, with remarkable reductions in natural gas consumption.

Conclusion: A Model for Future Innovations

River Road Colony’s successful upgrade serves as a compelling case for other agricultural operations and facilities considering similar technological advancements. The practical benefits and long-term savings from adopting such advanced systems are clear, promising not only reduced costs but also improved environmental outcomes.

Disclaimer:

The information presented in this blog post is based on calculated assumptions and data derived from a case study at River Road Colony, where the Reflect-O-Ray® system, marketed by Enviro-Smart Inc., demonstrated significant energy savings. These figures are intended for illustrative purposes only and should not be taken as guarantees of future savings or performance. Actual results may vary based on changes in energy prices, system usage, maintenance schedules, system configuration, and other operational conditions.

The Reflect-O-Ray® system is a product of Combustion Research Corporation and is protected by patents held by the company. This blog mentions specific systems for informational purposes and such mentions do not constitute an endorsement or critique of similar systems produced by other companies. The views and opinions expressed are those of Enviro-Smart Inc. and do not necessarily reflect the official policy or position of River Road Colony, Combustion Research Corporation, or any of its competitors.