In the crowded landscape of radiant tube-heating solutions, one system stands as the undisputed leader, cutting through the competition with unparalleled efficiency and innovation. Combustion Research Corporation’s (CRC) Reflect-O-Ray® emerges as a pioneer in this fiercely competitive arena, boasting over five decades of industry expertise. What sets Reflect-O-Ray apart is its distinctive low mass tubing, a revolutionary design that has become synonymous with CRC’s commitment to advancing radiant heating technology.

The Reflect-O-Ray Difference

CRC’s patented low mass 22-gauge aluminized steel alloy spiral tubing is the backbone of their radiant tube heating systems, redefining the standards for heat delivery. This tubing not only ensures quicker start-up times but also facilitates faster heat recovery and even temperature distribution further down the system. In stark contrast, competitors relying on all-black metal find themselves trapped in inefficiencies. These systems, characterized by heavier tubing throughout the system, struggle to match Reflect-O-Ray’s performance.

Reflect-O-Ray’s innovative design showcases its unique approach. Transitioning from a 10-foot 16-gauge combustion tube, Reflect-O-Ray adopts a low mass aluminized spiral tubing for the remainder of the system, ensuring a balanced and efficient heat distribution. The use of lighter gauge aluminum steel alloy tubing proves to be a game-changer, offering advantages that extend beyond mere efficiency.

Understanding Radiant Tube Heating

Radiant tube heating works by heating a tube to a high temperature, which then emits infrared radiation. This radiation travels through the air and heats objects and surfaces directly, rather than heating the air itself. The heated objects then re-radiate the heat, warming the surrounding air. For effective radiant output, the tubing needs to reach a sufficient temperature to emit infrared radiation. Low mass tubing allows for efficient conduction and convection, ensuring the tube heats up quickly and maintains the necessary temperature for effective radiant heating.

Understanding Heat Transfer in Metals: A Molecular Perspective

Heat transfer at the molecular level involves the movement of energy through vibrations and collisions of atoms or molecules. In metals, heat is primarily transferred through conduction and electron diffusion mechanisms. Metal objects like Reflect-O-Ray’s tubing, with simpler lattice structures and higher free electron density, exhibit superior thermal conductivity compared to heavier metals used in conventional radiant heating systems.

The Role of Gauge in Thermal Conductivity

Reflect-O-Ray’s 22-gauge aluminized steel spiral tubing strikes an optimal balance between durability and thermal efficiency. In contrast, conventional systems utilizing heavier 16-gauge metal encounter issues like heightened phonon scattering and compromised electron mobility, resulting in uneven heating.

Phonon Scattering and Thermal Efficiency

Phonon scattering occurs when vibrations (phonons) in the lattice structure of the metal are disrupted by imperfections or other phonons, reducing the efficiency of heat transfer. Heavy metals with complex lattice structures cause more phonon scattering, disrupting the smooth flow of thermal energy. Reflect-O-Ray’s 22-gauge aluminized spiral tubing minimizes these disruptions, allowing for more direct and efficient heat transmission, contributing significantly to overall energy efficiency.

Electron Mobility: Lighter vs. Heavier Metals

Reflect-O-Ray’s aluminized spiral tubing ensures optimal electron mobility, crucial for efficient heat transfer. Despite its lighter weight, the tubing maintains durability with external spiral bonding, minimizing stress points and weak spots, ensuring an extended lifespan for the radiant tube heating system.

Aluminized Steel: A Conductor’s Symphony

CRC’s patented aluminized spiral tubing enhances thermal performance with reflective properties of aluminum and the structural integrity of external spiral bonding, facilitating efficient heat transfer. The aluminized steel alloy’s high emissivity ensures that the tubing efficiently emits thermal radiation, effectively heating the surrounding environment. The aluminum coating also enhances reflectivity, directing more infrared radiation towards the target area and minimizing heat loss. This combination of high emissivity and reflectivity maximizes the efficiency of radiant heating.

Spiral Tubing Structural Integrity

The external spiral bonding of aluminum adds to the structural integrity of the tubing, making it more resistant to thermal expansion and contraction. This reinforcement ensures consistent heat transfer and prevents hot spots, enhancing the overall reliability and longevity of the system. The combination of high thermal conductivity, durability, and corrosion resistance makes Reflect-O-Ray’s tubing a superior choice for radiant heating applications.

Reflect-O-Ray’s aluminized steel is non-corrosive, making it ideal for long-term use. As the original dry-tube system, Reflect-O-Ray comes with a 10-year internal corrosion warranty. For applications where external humidity could be a concern, Reflect-O-Ray tubing is available in stainless steel, along with its burners, exhaust fans, and reflector shields, ensuring system longevity.

Efficiency in Radiant Heating

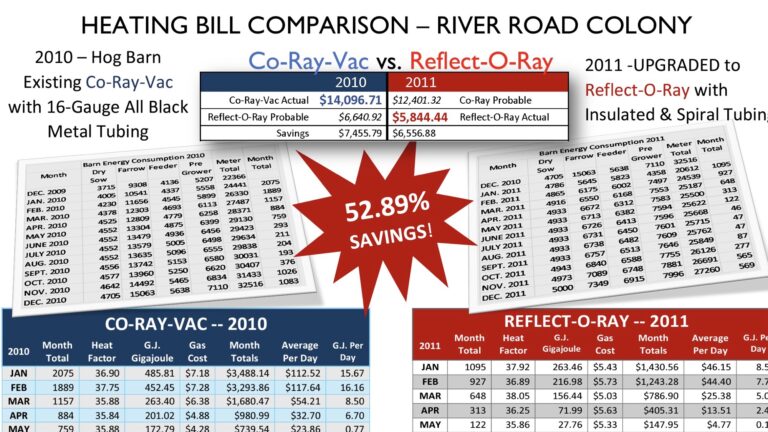

Reflect-O-Ray systems can be customized based on specific heating requirements, providing flexibility in installation and operation. This customization, combined with the high efficiency of the tubing, ensures wall-to-wall even temperatures with minimal differentials, reducing the need for multiple burners and lowering BTU requirements. As a result, Reflect-O-Ray systems are 30-50% more fuel-efficient than traditional black metal radiant systems.

Conclusion: Unlocking Efficiency and Innovation

Reflect-O-Ray’s aluminized steel spiral tubing outperforms typical competitor radiant tubing heaters in terms of radiant efficiency, start-up time, and heat distribution. By harnessing the power of low mass design and innovative technology, Reflect-O-Ray sets the standards for radiant heating performance, ensuring optimal comfort, productivity, and energy savings for a wide range of applications.