Harnessing the Power of Infrared Radiant Tube Heating for Poultry Facilities

In the dynamic world of poultry farming, maximizing production efficiency and ensuring the well-being of your flock are paramount. One innovative solution that has been revolutionizing the poultry industry is the implementation of infrared radiant tube heating systems, with Reflect-O-Ray leading the charge. In this blog post, we will delve into the myriad benefits of this cutting-edge technology, focusing on improved production rates, shortened days to market, its application across various indoor facilities, and its role as a disease prevention tool.

1. Unveiling the Reflect-O-Ray Advantage

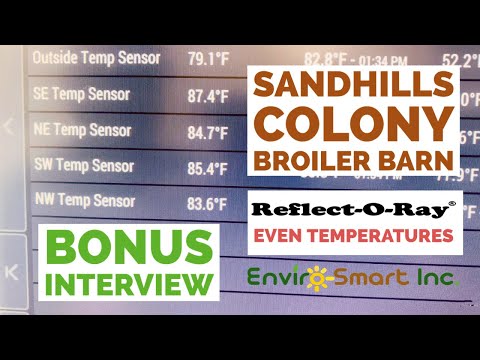

Reflect-O-Ray’s infrared radiant tube heating systems stand out for their ability to provide unparalleled warmth with remarkable precision. The technology ensures even heating from wall to wall, resulting in minimal temperature differentials of just 1-2 degrees. This meticulous control creates an optimal environment for poultry, fostering a stress-free atmosphere that directly contributes to enhanced production rates.

2. Swift Days to Market

In the competitive poultry industry, time is of the essence. Reflect-O-Ray’s efficient heating solutions play a pivotal role in reducing the days to market for your poultry products. The even distribution of infrared heat accelerates the growth rate of birds, promoting healthier and more robust development. This translates to a quicker turnaround from hatching to market-ready birds, giving your operation a strategic edge.

3. Tailored for All Indoor Poultry Facilities

Whether you operate turkey, broiler, or laying facilities, Reflect-O-Ray’s infrared radiant tube heating proves versatile and effective across the board. The adaptability of this technology ensures that each facility type benefits from consistent and reliable heating, creating an environment conducive to optimal poultry growth.

4. Precision in Temperature Control

The one-degree temperature differentials achieved by Reflect-O-Ray’s infrared radiant tube heating are not merely a statistic; they represent a game-changer in the poultry farming landscape. Maintaining such precision in temperature control is instrumental in preventing stress-related issues among the flock, ultimately promoting better overall well-being and productivity.

5. Mimicking Nature: Infrared as a Stimulant

Infrared heating is designed to replicate the natural warmth provided by the sun, acting as a stimulant for animal production. The gentle and consistent heat generated by Reflect-O-Ray’s radiant heating mimics the sun’s rays, triggering positive physiological responses in poultry. This stimulation enhances feed conversion rates, nutrient absorption, and overall growth, leading to healthier and more productive flocks.

6. Economic Efficiency

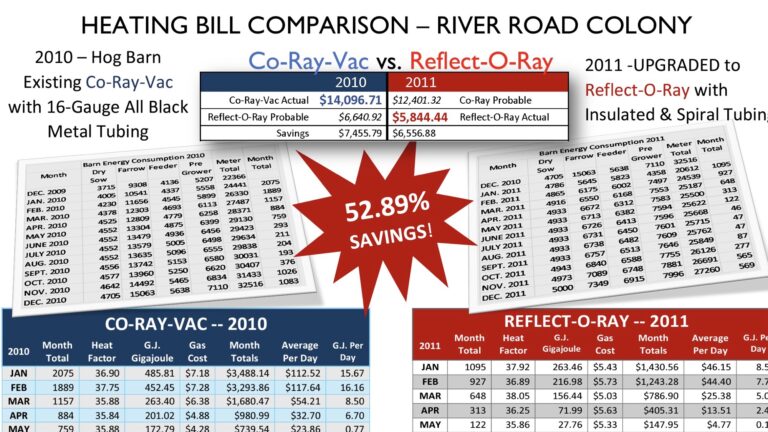

Beyond its benefits for poultry well-being and production, Reflect-O-Ray’s infrared radiant tube heating is also economically efficient. The precise temperature control minimizes energy waste, ensuring that every unit of energy expended contributes directly to maintaining the ideal conditions for your flock.

Reflect-O-Ray is notorious for delivering exceptional efficiency, with up to 50% or more in fuel savings when compared to conventional heating methods like hot water, underfloor heating, and unit box heaters. Even when stacked against other heavy, all-black metal pressure radiant systems, Reflect-O-Ray stands out as more fuel-efficient. This superiority is attributed to its innovative design, featuring lightweight 22-gauge aluminized spiral tubing, insulated tubing, and vacuum vented exhausting.

7. Enhancing Ventilation: Infrared as a Catalyst for Air Circulation

In addition to its remarkable contributions to enhanced production and accelerated days to market, infrared radiant tube heating emerges as a vital component in a comprehensive disease prevention toolkit for poultry facilities.

Reflect-O-Ray’s infrared technology uniquely influences air circulation without compromising warmth. While proper ventilation is essential for maintaining a healthy environment, conventional heating methods, such as underfloor or unit heaters, often pose challenges in colder months. The heat sink effect of Reflect-O-Ray facilitates ventilation even in chilly weather, offering a distinct advantage over traditional barn heating systems.

This innovative approach allows for the necessary exchange of air without causing discomfort to the poultry. The controlled warmth provided by Reflect-O-Ray’s infrared radiant tube heating mitigates the drawbacks associated with cold-weather ventilation, ensuring that your facility maintains optimal conditions for both poultry health and disease prevention.

Furthermore, this ability to regulate ventilation in colder months contributes to a more dynamic and adaptable poultry farming environment. Reflect-O-Ray’s technology not only promotes disease prevention but also aligns with the importance of proper air circulation, creating a harmonious balance between warmth and ventilation throughout the year.

In summary, incorporating infrared radiant tube heating from Reflect-O-Ray into your poultry facility is not only a strategy for improved production and faster days to market but also a proactive measure in disease prevention. The technology’s role in maintaining biosecurity, reducing stress, and creating an inhospitable environment for pathogens positions it as an indispensable tool in safeguarding the health and well-being of your flock. Elevate your disease prevention efforts with Reflect-O-Ray’s infrared radiant tube heating systems for a poultry facility that thrives in all seasons.